Page 1 - lw3481

P. 1

I

Towner JOB REPORT

I

TOWNER MANUFACTURING COMPANY - P. 0. BOX 6096- SANTA ANA, CALIFORNIA 92706, U.S.A.

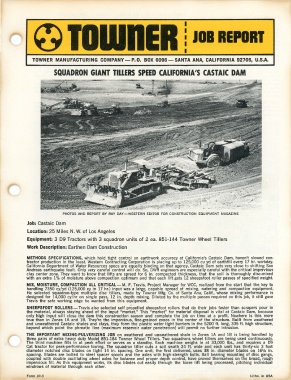

SQUADRON GIANT TILLERS SPEED CALIFORNIA'S CASTAIC DAM

PHOTOS AND REPORT BY RAY DAY-WESTERN EDITOR FOR CONSTRUCTION EQUIPMENT MAGAZINE

Job: Castaic Dam

Location: 25 Miles N. W. of Los Angeles

Equipment: 3 D9 Tractors with 3 squadron units of 2 ea. 851-144 Towner Wheel Tillers

Work Description: Earthen Dam Construction

METHODS SPECIFICATIONS, which hold tight control on earthwork accuracy at California's Castaic Dam, haven't slowed con-

tractor production in the least. Western Contracting Corporation is placing up to 125,000 cu yd of earthfill every 17 hr. workday.

California Department of Water Resources specs are equally binding on that agency. Castaic Dam sets very close to shifting San

Andreas earthquake fault. Only very careful control will do. So, DWR engineers are especially careful with the critical impervious

clay center zone. They want to know that lifts are spread for 6 in. compacted thickness, that the soil is thoroughly disc-mixed

with an extra 1 % of moisture above compaction optimum and that each lift gets 12 sheepsfoot rolle_r passes of specified weight.

MIX, MOISTURE, COMPACTION ALL CRITICAL- M. F. Travis, Project Manager for WCC, realized from the start that the key to

handling 7350 cy/yd (125,000 cy in 17 hr.) input was a large, capable spread of mixing, watering and compaction equipment.

He selected squadron-type multiple disc tillers, made by Towner Mfg. Co. of Santa Ana, Calif., whose mixing performance is

designed for 14,000 cy/hr on single pass, 12 in. depth mixing. Diluted by the multiple passes required on this job, it still gave

Travis the safe working edge he wanted from this equipment.

SHEEPSFOOT ROLLERS- Travis also selected self propelled sheepsfoot rollers that do their jobs faster than scrapers pour in

the material, always staying ahead of the input "market." This "market" for material disposal is vital at Castaic Dam, because

only high input will close the dam this construction season and complete the job on time at a profit. Nowhere is this more

true than in Zones lA and 18. They're the impervious, fine-grained zones in the center of the structure. Built from weathered

and unweathered Castaic shales and clays, they form the plastic water tight barriers in the 5200 ft. long, 335 ft. high structure,

beyond which point the phreatic line (maximum reservoir water penetration) will permit no further intrusion.

THE IMPORTANT MIXING-PULVERIZING JOB on weathered and unweathered shale in Zones lA and 1B is being handled by

three pairs of extra heavy duty Model 851-184 Towner Wheel Tillers. Two squadrons wheel tillers are being used continuously.

The third machine fills in at peak effort or serves as a standby. Each machine weighs in at 33,000 lbs., and requires a D9

Cat tractor for peak-performance towing. The squadron tiller cuts a soil swath 24 ft. wide and each unit has thirty-six 3 foot

diameter notched disc blades on tight 14 in. spacing. One unit, the first delivered, uses 38 in. diameter blades on 16¼ in.

spacing. Blades are bolted to steel spacer spools and the axles with high-strength bolts. Ball bearing mounting of disc gangs,

coupled with double oscillating wheel axles for balance and proper depth control, have proved themselves on the broad, rough

impervious fill. As this equipment works, its disc blades cut easily through the loose lift being processed, pitching individual

windrows of material through each other.

Form JR-3 Litho. in USA