Page 354 - us_mineralresources1885

P. 354

:

338 MINERAL RESOURCES.

The ash fioiii the calm is, of course, left iu the residuum, mtikiug it

leaner and adding a most objectionable amount of silica and alumina.

The clinker, as it comes from the oxide furnaces, is partly in flat cakes,

about 2 inches thick and from 4 to 10 inches in diameter, and partly in

small fragments, from dust to 2 inches in diameter. It is screened be

fore going to the blastfurnaces, the very fine portion being rejected.

The coarse clinker very frequently varies between certain limits, as

shown by the following analyses

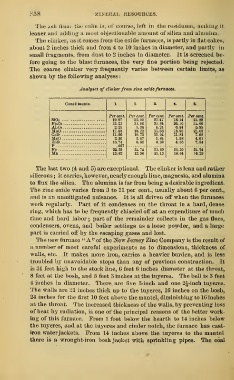

Analyses of clinker from zinc oxide furnaces.

Constituents. 4.

Per cent. Per cent. Per cent. Per cent. Percent.

SiOs . 19.97 25.03 23. 47 18.14 21.29

FesOs 33.21 31.06 33.84 36.16 31.06

AI2O3 2.25 6.36 8.24 6.94 5.98

MnO. 17.83 16.22 15.66 18.90 21.03

CaO . 11.96 10.73 11.04 11.81 7.60

MgO. 2.30 2.67 1.84 1.98 4.01

ZnO.. 10.74 6.98 4.98 4.06 7.84

P .... .037

re... 23.25 21.74 23.69 25.30 21.74

Mn .. 13.82 12.56 12.13 14.64 16.29

The last two (4 and 5) are exceptional. The clinker is lean and rather

it carries, however, nearly enough lime, magnesia, and alumina

siliceous ;

to flux the silica. The alumina is far from being a desirable ingredient.

The zinc oxide varies from 3 to 11 per cent., usually about 6 per cent.,

and is an unmitigated nuisance. It is all driven off when the furnaces

work regularly. Part of it condenses on the throat in a hard, dense

ring, which has to be frequently chiseled off at an expenditure of much

time and hard labor part of the remainder collects in the gas flues,

;

condensers, ovens, and boiler settings as a loose powdea", and a large

part is carried off by the escaping gases and lost.

The new furnace " A " of the ISTew Jersey Zinc Company is the result of

a number of most careful experiments as to dimensions, thickness of

walls, etc. It makes more iron, carries a heavier burden, and is less

troubled by unavoidable stops than any of previous construction. It

is 31 feet high to the stock line, 6 feet 6 inches diameter at the throat,

8 feet at the bosh, and 5 feet 3 inches at the tuyeres. The bell is 3 feet

4 inches in diameter. There. are five 3-inch and one 2^-inch tuyeres.

The walls are ;il inches thick up to the tuyeres, 16 inches on the bosh,

24 inches for the first 10 feet above the mantel, diminishing to IG inches

at the throat. The increased thickness of the walls, by preventing loss

of heat by radiation, is one of the principal reasons of the better work-

ing of this furnace. From 1 foot below the hearth to 14 inches below

the tuyeres, and at the tuyeres and cinder notch, the furnace has cast-

iron water jackets. Prom 14 inches above the tuyeres to the mantel

there is a wrought-iron bosh jacket with sprinkling pipes. The coal