Page 7 - doi_preservationbrief15

P. 7

base concrete. The higher cement content in the facing

concrete provided a more water-resistant outer layer

and finished surface. The application of a cement-rich

top layer, referred to in some early concrete publications

as "waterproofing," was also used on top surfaces of

concrete walls, or as the top layer in sidewalks. With this

type of concrete construction, deterioration can occur

over time as a result of debonding between layers, and

can proceed very rapidly once the protective cement-rich

layer begins to break down.

It is common for historic concrete to have a highly

variable appearance, including color and finish texture.

Different levels of aggregate exposure due to paste

erosion are often found in exposed aggregate concrete.

This variability in the appearance of historic concrete

increases the level of difficulty in assessing and repairing

weathered concrete.

Signs of Distress and Deterioration

Characteristic signs of failure in concrete include

cracking, spalling, staining, and deflection. Cracking

occurs in most concrete but will vary in depth, width,

direction, pattern, and location, and can be either active

or dormant (inactive). Active cracks can widen, deepen,

or migrate through the concrete, while dormant cracks

remain relatively unchanged in size. Some dormant

cracks, such as those caused by early age shrinkage of

the concrete during curing, are not a structural concern

but when left unrepaired, can provide convenient

channels for moisture penetration and subsequent

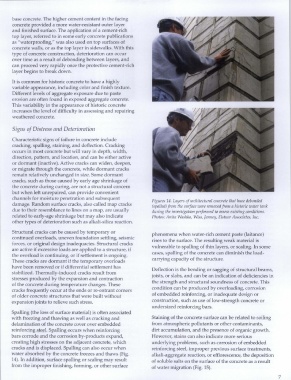

Figures 14. Layers of architectural concrete that have debonded

damage. Random surface cracks, also called map cracks (spaUed) from the surface were removed from a historic water tank

due to their resemblance to lines on a map, are usually during the investigation performed to assess existing conditions.

related to early-age shrinkage but may also indicate Photos: Anita Washko, Wiss, Janney, Elstner Associates, Inc.

other types of deterioration such as alkali-silica reaction.

Structural cracks can be caused by temporary or

phenomena when water-rich cement paste (laitance)

continued overloads, uneven foundation settling, seismic

rises to the surface. The resulting weak material is

forces, or original design inadequacies. Structural cracks

vulnerable to spalling of thin layers, or scaling. In some

are active if excessive loads are applied to a structure, if

cases, spalling of the concrete can diminish the load-

the overload is continuing, or if settlement is ongoing.

carrying capacity of the structure.

These cracks are dormant if the temporary overloads

have been removed or if differential settlement has

Deflection is the bending or sagging of structural beams,

stabilized. Thermally-induced cracks result from

joists, or slabs, and can be an indication of deficiencies in

stresses produced by the expansion and contraction

the strength and structural soundness of concrete. This

of the concrete during temperature changes. These

condition can be produced by overloading, corrosion

cracks frequently occur at the ends or re-entrant corners

of embedded reinforcing, or inadequate design or

of older concrete structures that were built without

expansion joints to relieve such stress. construction, such as use of low-strength concrete or

undersized reinforcing bars.

Spalling (the loss of surface material) is often associated

with freezing and thawing as well as cracking and Staining of the concrete surface can be related to soiling

delamination of the concrete cover over embedded from atmospheric pollutants or other contaminants,

reinforcing steel. Spalling occurs when reinforcing dirt accumulation, and the presence of organic growth.

bars corrode and the corrosion by-products expand, However, stains can also indicate more serious

creating high stresses on the adjacent concrete, which underlying problems, such as corrosion of embedded

cracks and is displaced. Spalling can also occur when reinforcing steel, improper previous surface treatments,

water absorbed by the concrete freezes and thaws (Fig. alkali-aggregate reaction, or efflorescence, the deposition

14). In addition, surface spalling or scaling may result

of soluble salts on the surface of the concrete as a result

from the improper finishing, forming, or other surface

of water migration (Fig. 15).

7